Broad opportunities in a compact casing

The new series of Klimor EVO ventilation and air-conditioning units launched to the market opens new opportunities to select devices which are Efficient, Versatile and Optimum in terms of costs of purchase and operation, for various sectors of the ventilation trade.

However, many projects require use of ventilation units with compact design, processing air in the range expected most often, ready to work right after their installation, in plug & play mode*).

EVO SMART SOLUTION group solutions respond to these needs.

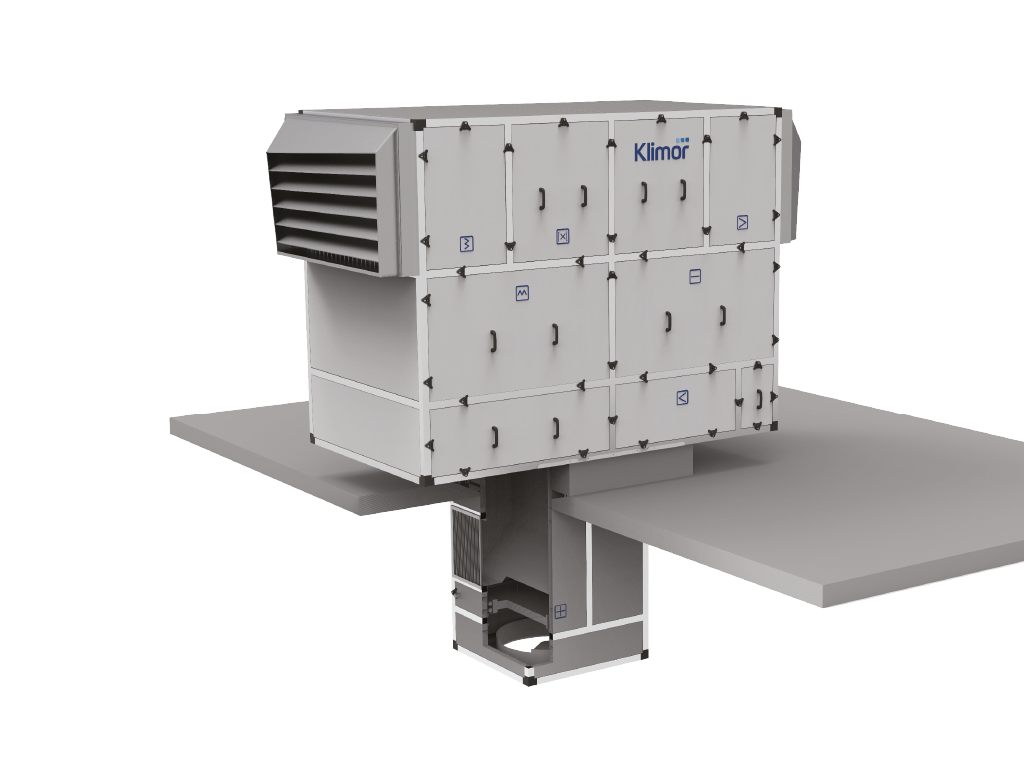

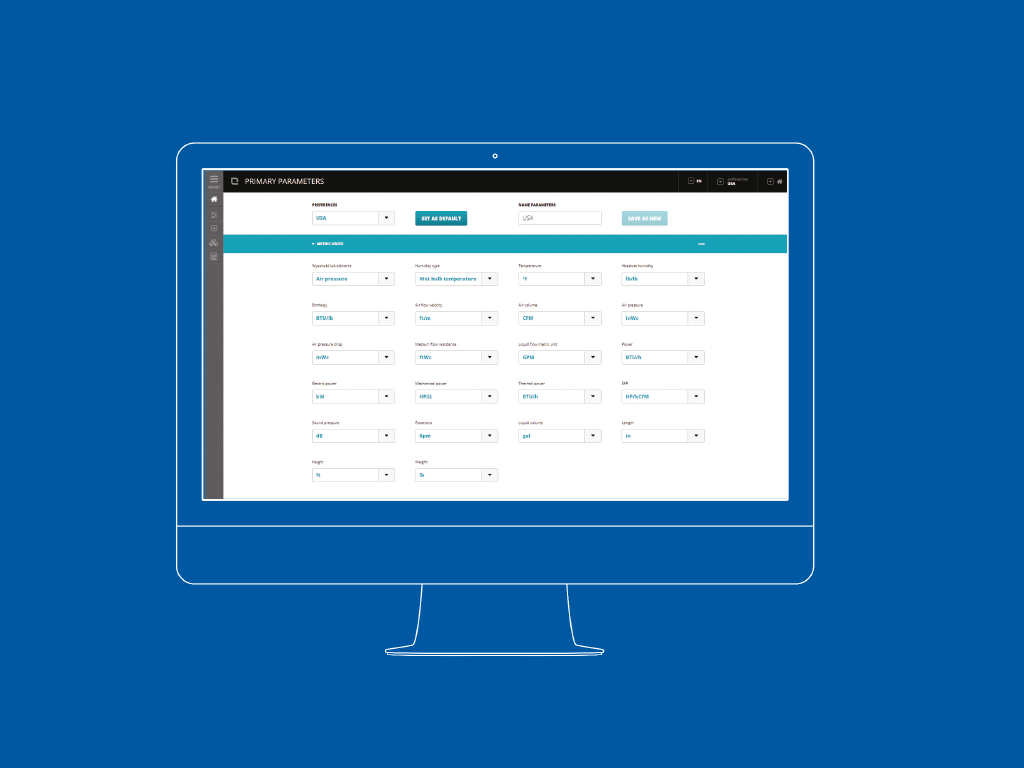

EVO-S COMPACT

Maximum efficiency and minimum flow resistance of heat recovery exchangers, achieved thanks to optimally selected dimensions of particular sizes.

- 11 sizes, optimum for flows from 500 to 16 900m3/h

COMPACT with model configuration with air supply and exhaust fans placed downstream the heat exchanger, makes it possible to achieve balanced distribution of pressures in the heat recovery section, limits unwanted recirculation and provides effective exchange of air to fresh one. This solution is particularly important in units with a rotary regenerator.

COMPACT equipment covers the functions of standard air supply and exhaust ventilation, installed in a compact casing:

- Cartridge, bag or mini-pleat filters in classes: ePM1, ePM2,5, ePM10

- Rotary regenerator or cross-flow/counterflow heat exchanger

- EC fans with highly efficient drives and a broad range of adjustment, adapted to cooperate with CAV constant air flow adjustment or VAV constant pressure adjustment.

- Water or electric heater.

PERIPHERAL equipment supplements the central unit with additional functions, installed in the same casing standard:

- Reversion water coolers or direct expansion coolers, with a droplet separator and a triple-slope AISI 304 stainless steel drain tray

- Silencers with a possibility to select attenuation strength

- Secondary, bag or mini-pleat filters in classes: ePM1, ePM2,5, ePM10

Rotary regenerator with a flush sluice in connection with configuration of fans on opposite sides, minimizes recirculation of exhaust air and provides efficiency of air exchange to fresh one.

Cross flow/counterflow air exchanger with cross countercurrent or concurrent air flow, equipped with a 100% by-pass, enabling the use of free-cooling function.

EVO-T COMPACT

It is a series of suspended ventilation and air conditioning units with the height up to 355 mm, with concurrent or cross air flow in the heat recovery section.

- 3 sizes optimum for flows from 500 to 2 450m3/h

100% by-pass enables cutting-off the heat exchanger from air flow in the transitional period and in order to provide free-cooling

COMPACT equipment covers the functions of standard air supply and exhaust ventilation, installed in a compact casing:

- Cartridge or mini-pleat filters in classes: ePM1, ePM2,5, ePM10

- Cross flow/counterflow heat exchanger with cross or concurrent air flow.

- EC fans with highly efficient drives and a broad range of adjustment

- Water or electric heater

PERIPHERAL equipment supplements the central unit with additional functions, installed in the same casing standard:

- Water or direct expansion coolers, with a droplet separator or AISI 304 stainless steel drain tray

- Silencers

- Secondary bag filters in classes: ePM1, ePM2,5, ePM10

Cross flow/counterflow air exchanger with cross or concurrent air flow, equipped with a 100% by-pass, enabling the use of free-cooling function.

EVO-RX

It is a series of complete ductless devices providing air exchange, heat and cold supply in large-size structures.

- 2 sizes designed for flows from 3 750 to 9 200m3/h

Reversion cooler installed in the external part of the unit, over the ceiling, facilitates direct connection to a condensation unit or ice water unit, and vertical position of the exchanger and the droplet separator on a triple-slope drain tray makes it possible to manage condensate drain during operation.

Heater installed in the internal part of the unit, under the ceiling, is less exposed to freezing, and since the automation uses factory-mounted no-frost capillary, this risk is minimized.

The equipment covers functions of standard air supply and exhaust ventilation, installed in compact casing:

- Mini-pleat filters in classes: ePM1, ePM2,5, ePM10

- Cross flow/counterflow heat exchangers

- EC fans with highly efficient drives and a broad range of adjustment, adapted to cooperate with CAV constant air flow adjustment or VAV constant pressure adjustment

- Water heater

- Reversion water coolers or direct expansion coolers, with a droplet separator

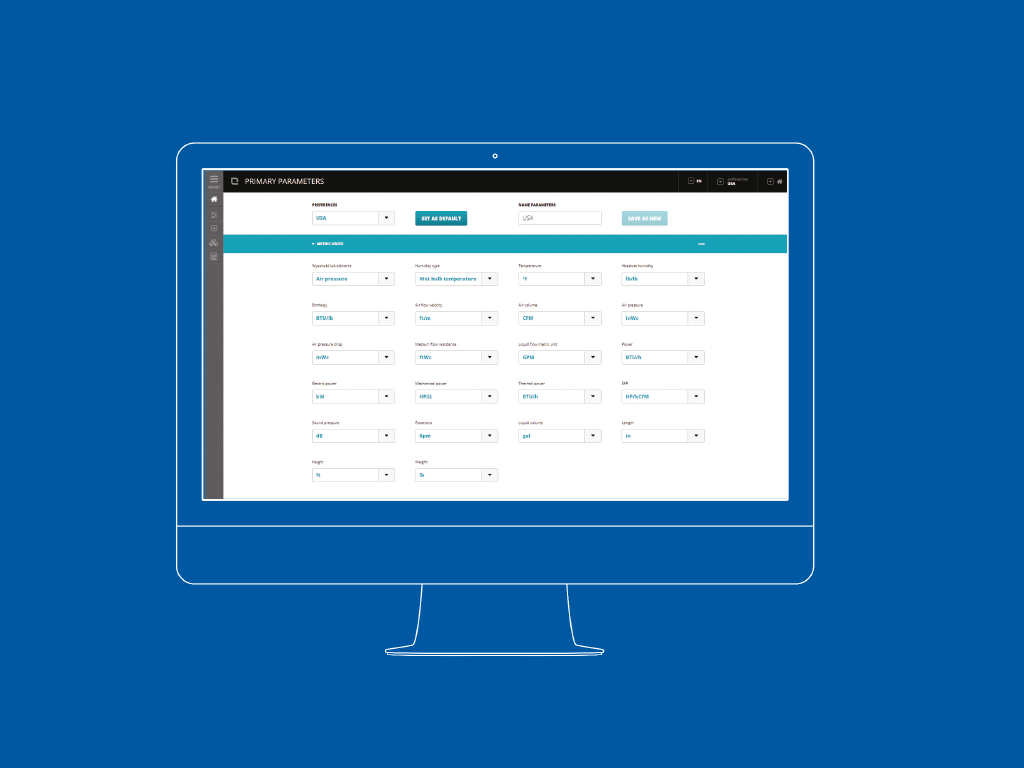

Plug & play automation

Plug & play automation installed and wired inside the central unit*) in options for all available equipment configurations. Visualization and management of units operation is possible thanks to an intuitive HMI Touch panel available in sizes: 4.3” and 7.0” and a web browser**)

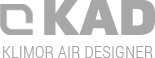

Configuration of sizes and subassemblies based on the expected hydraulic, thermodynamic and air quality parameters, provided in the original Klimor Air Designer selection software based on individual project needs.

*) Plug & play solution available for COMPACT units. It does not include wiring of control valves of heaters and coolers. In the case of the option of a unit with an electric heater, the control cabinet of the heater is mounted outside the device.

**) After prior internet connection.

Polish

Polish English

English German

German Swedish

Swedish Spanish

Spanish Eastern Region

Eastern Region

Return to main menu

Return to main menu